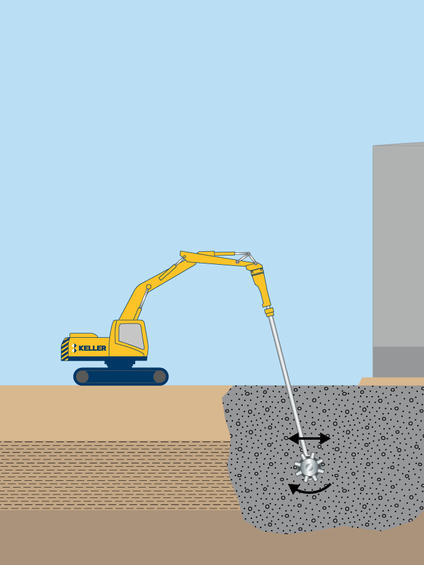

Mass Soil Mixing (MSM), or mass stabilisation, is a ground improvement technique that improves soft or loose soils, by mechanically mixing them with either wet grout or dry cementitious binder.

Common uses

Process

The mass soil mixing process is typically constructed in pre-defined ‘cells’ of the order of 4m x 4m in plan area. Commonly the cells are mixed adjacent to others to form a 100% mass stabilised zone, all with a designed strength and stiffness.

Soils vary widely in their ability to be mixed, depending on the soil type, strength, water content, plasticity, stratigraphy, and texture. Organic soil and peats can often be stabilised, but laboratory testing is always recommended prior to design.

Treatment is possible to depths up to 5m to 6m.

Large obstructions are pre-excavated to remove ahead of the soil mixing process.

Pre-production laboratory testing is used to determine the mix methodology, energy, and binder content. Keller has developed proprietary equipment and software for the real-time control and monitoring of mixing parameters during the mixing process. Samples are taken of during production and cured in a controlled environment for testing.

Advantages

Quality assurance

Quality is controlled and assured through column installation protocols and the results of relevant laboratory and field-verification tests. Each column is provided with a chart-log, which typically comprises: element identification, mixing tool details, mixing depth, mixing time, slurry specification, injection flow rate and pressure, total volume of slurry used, mixing tool velocities and rpm during penetration and withdrawal and torque of the shaft.

The mixing energy and binder content is calculated from this information to match design requirements.

Specimens of stabilised soils for testing are usually obtained from fresh columns with a wet grab.

Advanced core drilling and other field-testing methods can also be used to obtain specimens and to inspect the continuity, uniformity and stiffness of deep soil mixing columns. The selection of suitable verification methods depends on their relevance, accuracy and applicability in relation to the purpose and pattern of soil treatment and design properties of stabilised soil.